Car 3D printing is not particularly new in the current context, and many friends should also have some understanding of it. However, although this technology has appeared for a long time, it has not been popularized. However, with the continuous development of technology, this technology has gradually become popular, and many luxury car brands are also starting to apply this technology.

Which car models are currently using 3D printed car parts?

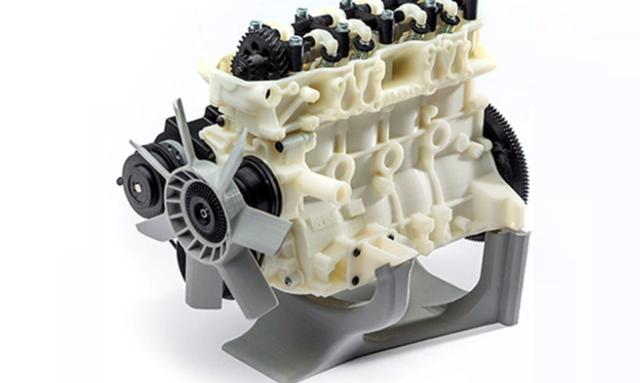

In terms of component manufacturing, 3D printing technology provides a more efficient and convenient technology. This technology allows major manufacturers to achieve rapid innovation, and it is also a very new thing for us car owners. So what is its magic?

Currently, this technology has been widely applied in the manufacturing of automotive components, and its advantages are also evident for complex component manufacturing. 3D printing technology has been widely used in the automotive industry, and various components may be created using this technology. It can be said that it is very impressive and even more outstanding. Do you recognize it?

Firstly, it can be quickly formed with high accuracy, and secondly, the research and development cycle is quite short. In this way, there will be a lot of savings in car manufacturing costs, which can be said to be a technology highly valued by car manufacturers. Secondly, it can also choose a variety of materials, which can bring higher quality and avoid some high consumption caused by design errors.

Bucket chair

What are the cars that have applied 3D printing technology? Firstly, Porsche already has it. Through research and use of 3D printing technology, they can produce bucket seats in a completely new form. This seat can also replace traditional seats. The backrest part of this seat is manufactured using 3D printing technology, allowing customers to choose from three different hardness levels.

brake caliper

Secondly, Bugatti also uses 3D printing technology. In our inertial thinking, the components printed by this technology are often applied to some structures or general frameworks. But Bugatti has been applied to its brake calipers. This $3 million engine, equipped with 1500 horsepower, can be said to be able to create such a delicate part, and it can be seen that 3D printing technology is quite impressive.

Hub

The McLaren P1 is naturally not willing to fall behind. They applied this technology to the wheels and created 3D printed wheels. Although this wheel is specifically designed for the McLaren P1 model, it is not produced by McLaren officially, but developed by HRE Wheel Manufacturing Company in the United States. This wheel is made of titanium alloy material, which can be said to have astonishing strength, Even its components are more outstanding than those produced by conventional methods.

And MINI's 3D printed personalized interior

3D printing accessories for Mercedes Benz trucks

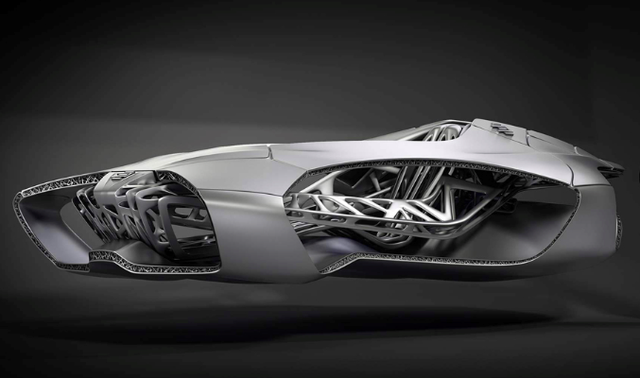

Honda has exhibited a car, with almost all parts except for the body structure printed in 3D.

YOYO with 3D printing for the entire vehicle, 5999 euros per unit

Volkswagen is looking for another way. They are not printing parts, but printing tools. For example, a wheel protection fixture costs thousands of euros per set, but using 3D printing for manufacturing only costs 20 euros.